Products

Climatic Environmental Test Chamber

High Temperature Aging Tester

Ventilation Type Aging Test Chamber

Composite Corrosion Test Chamber

Formaldehyde Test Chamber

Rapid Temperature Change Test Chamber

High & Low Temperature Low Pressure Test Chamber

High & Low Temperature Test Chamber

Muffle Furnaces

Precision Oven

Sand & Dust Test Chamber

Standard Salt Spray Test Chamber

Constant Temperature & Humidity Test Chamber

Two-chamber Thermal Shock Tester

Three-chamber Thermal Shock Tester

Heat Flow Meter

UV Weathering Test Chamber

Vacuum Oven

Walk-in Constant Temperature & Humidity Room

Xenon Lamp Aging Test Chamber

Rain Simulation Water Proof Test Chamber

Formaldehyde VOC Emission Test Chamber

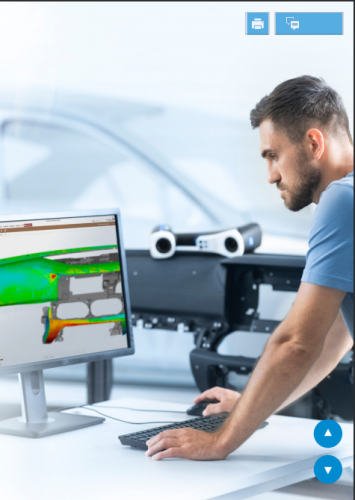

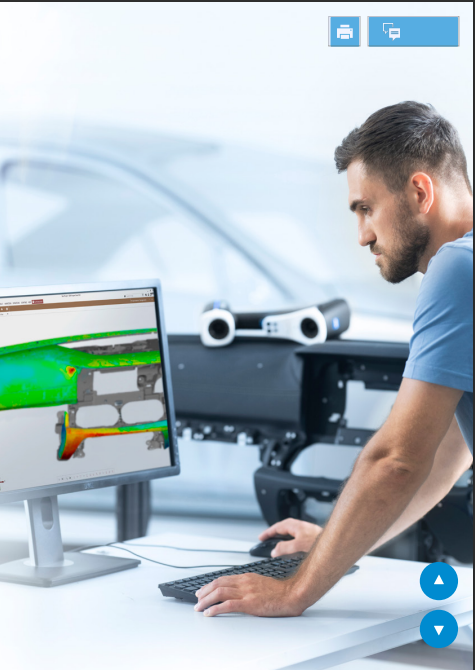

Optical Measuring Machine

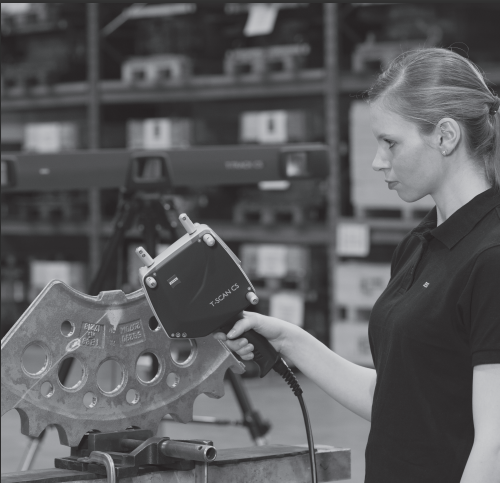

Blue Laser 3D Scanner

Water Drop Angle Measuring Instrument

Automatic Splicing Measuring Instrument

2.5D High-precision Automatic Video Measuring Instrument

Cantilever Automatic Video Measuring Instrument

Composite Coordinate Measuring Machine

2.5D High-precision Manual Video Measuring Instrument

Ultra-large Stroke Automatic Video Measuring Instrument

Fully Automatic Flash Point Apparatus

Video Measuring Microscope

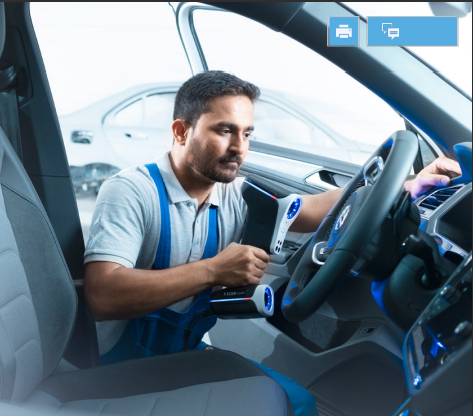

Laser 3D Scanner

Digital Vertical Measuring Projector